Top 5 Plastic Injection Molding Factories in TAIWAN

Taiwan is home to some of the world’s leading manufacturers of plastic injection molding. These factories are renowned for utilizing the latest technology and employing skilled workers. Taiwanese companies are now producing parts that are used worldwide. They range from industrial to automotive applications. In this article, we will introduce you to the top 5 plastic injection molding factories in Taiwan. We have selected these Taiwanese companies based on their experience and the services they offer. Let’s take a look at each of them!

5 Reliable Plastic Injection Molding Factories in TAIWAN

Taiwan makes high-quality plastic parts using advanced technology. However, many people feel sceptical when choosing Taiwanese companies. The reason is that the brands working in Taiwan are immature and can compromise on quality. Very few brands in that country offer reliable plastic injection molding service.

If you care about quality, I would suggest choosing GBM Mold. It is a Chinese company that offers high-quality injection molding services at very affordable prices. They also offer free delivery of your products. Sounds interesting? Contact the official team.

Having many low-quality factories in Taiwan makes it challenging to select hidden gems. Finding high-quality factories requires time and effort in research. However, I’ve done the research and found some of the best and reliable Taiwanese companies. You can trust them and get high-quality injection molding service.

Long New Group

Long New Group was founded in 1984. The company comprises three divisions, each focusing on a distinct type of injection molding. They produce products for industries such as automotive, electronics, and home appliances. They have also opened a plant in India. The molds they built are made to last, ensuring the extended lifespan of injection molds.

One of the things that makes it stand out is its consistent focus on technology. The Long New Technology & Research Co., Ltd works on innovative technology. This helps the country to have a competitive edge in the market. They also offer excellent customer service, enabling them to provide a solution tailored to their needs. Their commitment to quality ensures efficient and consistent production.

They are certified by Taiwantrade as Advanced Verified and hold CSA certification. They meet high international standards. Long New Group is a trusted choice for plastic injection molding, both in Taiwan and globally. They take pride in the precision of their products. They make each product according to the specifications set by the customer.

One of the things that makes it stand out is its consistent focus on technology. The Long New Technology & Research Co., Ltd works on innovative technology. This helps the country to have a competitive edge in the market. They also offer excellent customer service, enabling them to provide a solution tailored to their needs. Their commitment to quality ensures efficient and consistent production.

They are certified by Taiwantrade as Advanced Verified and hold CSA certification. They meet high international standards. Long New Group is a trusted choice for plastic injection molding, both in Taiwan and globally. They take pride in the precision of their products. They make each product according to the specifications set by the customer.

Mony Industrial

Mony Industrial was established in 1977. They specialize in plastic injection molding, including double-shot and triple-shot molding. Mony handles everything from part assembly to printing, painting, and laser marking. Over the years, Mony has built or adjusted thousands of molds to meet customer needs. The company is recognized for its innovation and expertise in handling complex projects.

Mony employs strict quality control and continually improves its business and products. In 2018, Mony obtained the IATF 16949 certificate, enabling it to enter the automotive market. They focus on providing high-quality products on time while ensuring customer satisfaction. Their factory in Tainan is equipped with the latest technology, helping them deliver quick services.

Mony has annual sales exceeding USD 20 million and is continually developing new product ideas to meet the global market. The company is known for its versatility and ability to produce both small and complex parts. Mony Industrial also prioritizes environmental care. They employ eco-friendly practices in their production processes, which helps reduce waste.

Mony employs strict quality control and continually improves its business and products. In 2018, Mony obtained the IATF 16949 certificate, enabling it to enter the automotive market. They focus on providing high-quality products on time while ensuring customer satisfaction. Their factory in Tainan is equipped with the latest technology, helping them deliver quick services.

Mony has annual sales exceeding USD 20 million and is continually developing new product ideas to meet the global market. The company is known for its versatility and ability to produce both small and complex parts. Mony Industrial also prioritizes environmental care. They employ eco-friendly practices in their production processes, which helps reduce waste.

Ann Tong

Ann Tong was founded in 1989 and is recognized for its comprehensive mold manufacturing services. The company specializes in micro-injection molding. This is ideal for producing small parts with minimal waste. Ann Tong works with both large and small companies, offering flexible production. Their focus on innovation enables them to meet the evolving needs of their clients. Their micro-injection molding machines have a smaller clamping force than regular machines. This process makes them ideal for creating detailed parts. They also offer hot runner molding, a technique that improves mold efficiency. Ann Tong also invests in the latest technology, which allows them to help clients achieve the best results. The company’s headquarters are located in New Taipei City, but it also has offices in countries such as Vietnam, Thailand, and Russia. Ann Tong’s global presence allows them to provide fast services to customers worldwide. The company holds certifications such as ISO 9001 and ISO 13485:2016. This indicates the company’s adherence to international quality standards.

Jier Chen

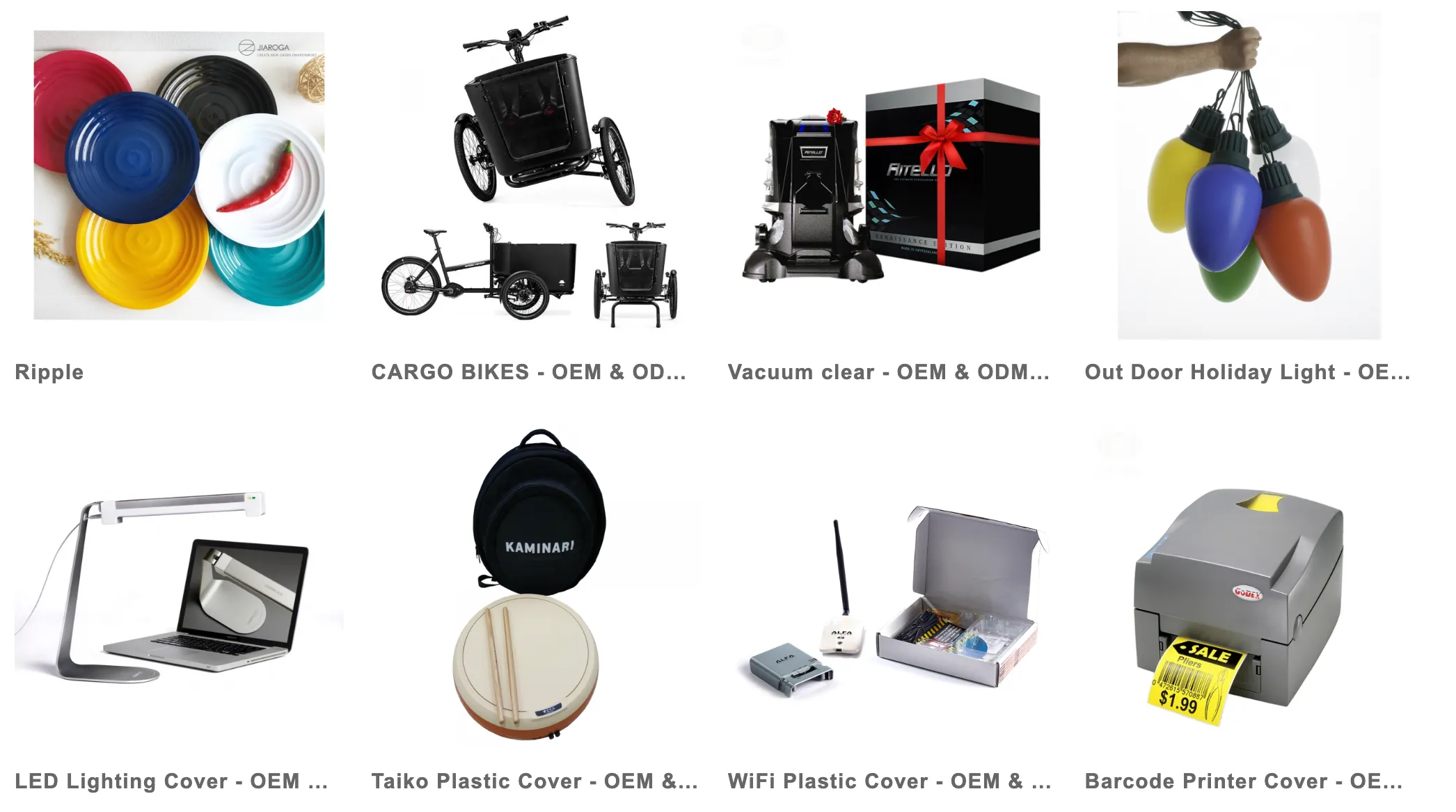

Jier Chen Enterprise was started in 1985. It is known for making plastic and metal parts using injection molding. The company offers product finishing, 3D printing, vacuum molding, and injection molding. They are also skilled at creating prototypes for new designs using advanced 3D printing. One of Jier Chen’s strengths is its ability to handle both large and small production runs. They use vacuum molding and soft tooling to make smaller batches of parts at a lower cost. This allows businesses to test new ideas before committing to a large order. Their machines and skilled workers enable them to produce both simple and intricate parts. Jier Chen collaborates with both OEMs and ODMs to cater to the diverse needs of various clients. They are known for their high-quality work and ability to deliver projects on time. Whether you need a small or large number of parts, Jier Chen can handle it.

SA CHEN Steel Mold Co., Ltd.

SA CHEN Steel Mold Co., Ltd. is a well-known company in Taiwan that makes high-quality plastic injection molds. It was founded in 1987 by the Lin brothers, and they now have over 35 years of experience. They also offer mass production services for making injection molding parts. The company is known for its precision and attention to detail. The company has a large factory that is 4,300m², which is big enough to handle molds that weigh between 50kg and 10 tons. They also have a special cleanroom where they make medical device parts. This is how they make sure these products are safe and meet strict standards. SA CHEN can create molds for many industries, like electronics and medical equipment.

SA CHEN does everything from designing the molds to machining and testing them. They are renowned for creating highly detailed and intricate molds. They are experts in creating specialized molds, such as double-density and thin-shell molds. The company utilizes advanced tools to ensure that each product is manufactured perfectly.

Tips for Selecting a Plastic Injection Molding Factory in Taiwan

As I mentioned at the outset, the Taiwanese market is not ideal for plastic injection molding. The factories in this part of the world tend to focus more on making a profit rather than offering value to their customers. In such cases, selecting a specific plastic injection molding factory becomes difficult.

You may fall victim to a factory offering low-quality plastic injection services. Here is a small checklist you must consider when shortlisting factories:

Experience

First, consider the company’s expertise. If a Taiwanese brand is relatively new and has no established history, it may be a good choice. The newer factories are not the best to trust.

Quality Standards

You should visit the factory and verify that they adhere to international standards. Those plastic injection factories that follow international standards generally produce high-quality parts.

Engineering Capabilities

Ideally, you should talk to engineers and the manufacturing team. This small meeting will help you know about the capabilities of a company. You should also ask for prototyping of plastic parts to get an idea.

Material Capability

Various types of plastics are utilized in the injection molding process. Those include ABS, PC, PEEK, PP, Nylon, and the list goes on. You should check if the company used your desired material or not. It is essential to verify material compatibility to prevent future issues.

Production Capacity

Can a Taiwanese company meet your specific production demand? That’s a big question you should ask the factory. If you want high production, I highly recommend choosing factories with extensive tools and machines.

Communication and Cost

The factors that offer customer support are considered reliable. You should also select a Taiwanese brand that provides after-sales service. Additionally, the company you choose should be affordable in the long run. I highly recommend avoiding factories that are premium and expensive.

Conclusion

Are you in Taiwan and looking for a reliable factor for plastic injection molding? Worry not, as this article will help you find one. Indeed, most of the factories in Taiwan are not trustworthy. However, some hidden gems go beyond expectations.

Their scrutiny takes time and patience. However, once you find them, you’ll love their value and over quality. In this article, I’ve discussed the five best companies that offer plastic injection molding factories. All of these brands are reliable and fall in the premium category. What I love about them is that they don’t overcharge the customers, which is a big plus.